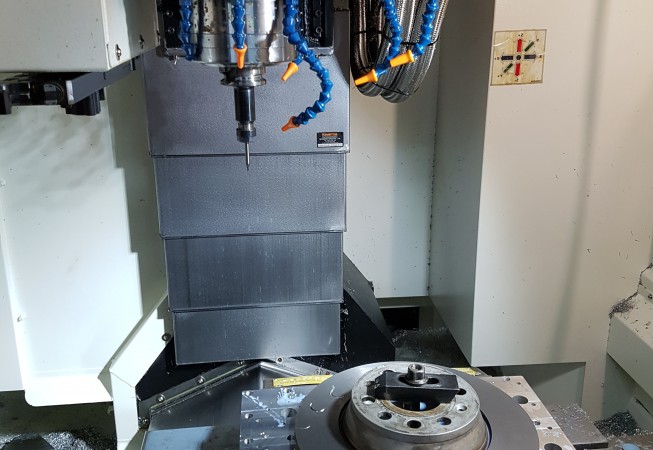

We redesign and fabricate customized automotive parts such as braking and suspension components, brake rotor bells, brake calliper brackets, customized camber plates, hubcentric spacers, fuelling and engine components requested by performance car garages who have unwavering trust in our quality and precision.

Such components are usually fabricated with aerospace grade steels, 6061-T6 or 7075-T6 aluminium, with hard anodizing or nitriding when required.

We also provide computerized brake disc turning, grooving and drilling services for garages and individuals with such needs, with tolerances surpassing international manufacturers’ standards.

Our computerized rotor turning process makes traditional skimming process seemingly stone-aged, as we achieve near perfect flat surfaces of +/- 0.010mm without over-skimming of disc material.